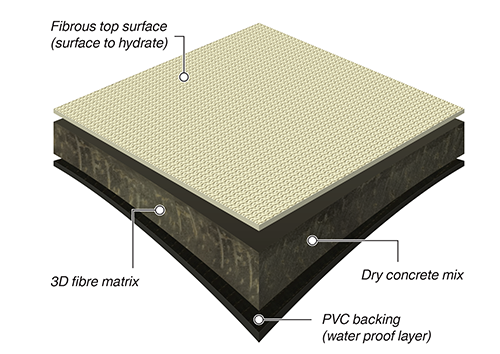

CC consists of a 3-dimensional fibre matrix containing a specially formulated dry concrete mix. A PVC backing on one surface of the CC ensures the material is completely water proof. CC can be hydrated by spraying or full immersion in fresh or salt water. Once set, the fibres reinforce the concrete, preventing crack propagation and providing a safe plastic failure mode, to provide a thin, durable, water proof and low-carbon concrete layer.

CC is available in 3 thicknesses: CC5™, CC8™ and CC13™, which are respectively 5, 8 and 13mm thick.

RAPID INSTALLATION

- CC can be laid at a rate of 200m²/hour, up to 10 times faster than conventional concrete solutions.

EASY TO USE

- Available in man-portable rolls. CC requires less plant, less personnel and no on-site mixing or measuring. Just add water.

LOWER PROJECT COSTSATION

- The speed and ease of installation mean CC is more cost-effective than conventional concrete, with less logistical burden. For example, a single lorry of CC8 can substitute for thirty-four 17T Mixer Trucks.

ECO FRIENDLY

- CC is a low mass, low carbon technology which uses up to 95% less material than conventional solutions. A single pallet of CC can cover the same area as two 17T mixer trucks for many applications.

CC KEY PROPERTIES

STRONG

The fibre reinforcement prevents cracking, absorbs energy from impact and provides a stable failure mode.

DURABLE

CC is twice as abrasion resistant as standard OPC concrete, has excellent chemical resistance, good weathering performance and will not degrade in UV.

FLEXIBLE

CC has good drape characteristics and will closely follow the ground profile and fit around existing infrastructure. Unset CC can be cut or tailored using basic hand tools.

WATER PROOF

The PVC backing on one surface of the CC ensures that the material has excellent impermeability.